Description

Your solar investment was probably a BIG investment. Guess what? If it’s not being inspected and maintained regularly, it can get a whole lot more expensive – fast. Solar plants (large or small) need routine maintenance and inspections to keep from losing money, voiding warranties or simply becoming a fire or shock hazard.

3fficient’s professional asset management service monitors your energy systems and quickly dispatches our nearby technicians, to get you back up and running safely – ASAP. So the next time your system goes down, you won’t find out about it weeks or months and thousands of dollars later. You’ll know right away and can rest assured the problem will be solved right away.

Terms & Conditions apply.

Scope of Work

Service Includes the following:

Every 6 months, String inverter(s):

- Check appearance/cleanliness of inverter cabinet, ventilation system and all exposed surfaces.

- Inspect, clean/replace inverter air filter elements.

- Check for corrosion on all inverter terminals, cables, and enclosure.

- Check all inverter fuses.

- Perform a complete visual inspection of inverter internally mounted equipment including subassemblies, wiring harnesses, contractors, power supplies, and all major components.

- Check condition of all the inverter AC and DC surge suppressors.

- Torque inverter terminals and all fasteners in electrical power connections.

- Check the operation of all inverter safety devices (E-stop, door switches).

- Record all operating voltages and current readings via the inverter front display panel.

- Record lifetime and instantaneous inverter power output including environmental data.

- Visual inspection of system to ensure safety and identify damaged/deficient components.

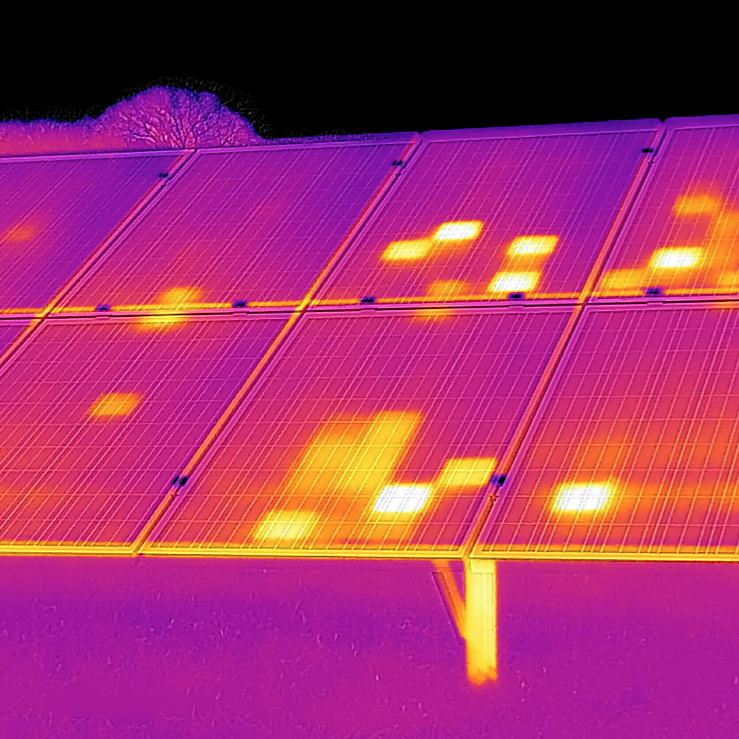

- Infrared inspection of inverters including thermal image report.

- Record all inspections completed and provide report to customer.

- Inform Customer and inverter manufacturer of all deficiencies identified.

Annual:

- Inspect all accessible electrical connections.

- Inspect all accessible electrical system components.

- Clean all electrical enclosures/switchgear.

- Infrared inspection of all major electrical components including thermal image report.

- Operating string testing (voltage, current, irradiance, back of module/ambient temperature).

- Visual inspection of structural components of array and supporting structure.

- System performance verification.

- Record all inspections completed and provide report to customer.

Notes:

- All waste is to be disposed of on site

- Sanitation facilities provided by others

- Materials provided by others must be UL listed and rated for the application

- All work to be done during normal business hours Monday – Friday 0700 – 1600

- All work to be done in a safe, clean, and workman like manner.

Exclusions:

- Module washing/cleaning

- Permits, fees or meetings are extra

- Changes or upgrades necessary to meet current code/AHJ requirements are extra

- Any additional items not detailed in “work to be done” section of this quotation.

Summer –

Seems to be worth it.

Max –

Helped us avoid issues and lost revenue, not once but twice. Definitely recommend.